Is it possible to control coating conditions?

Is it possible to control coating conditions?

Data processing realizes compatibility among the robots and faithful reproduction.

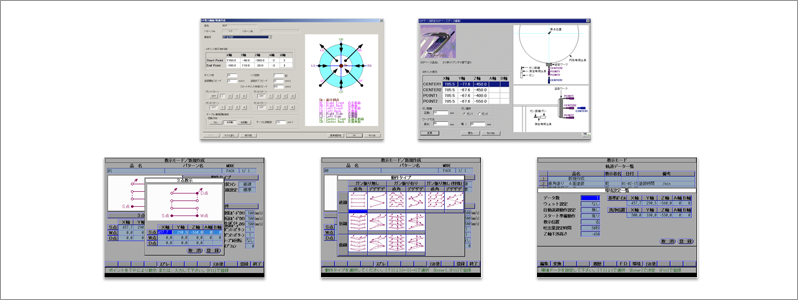

Data processing of all coating conditions

In robot coating, coating conditions are very important. The coating conditions used to depend on feelings of spray-man. Such analog management does not pass nowadays when every kind of demand such as diversification of additional decoration, upgrading of coating film, high productivity and low cost, is becoming more complicated. We developed a coating system to control data processing with numerical values introducing “Digital Coating” in SOFTBOY PRO series from an early stage. Line Dancer follows the concept, too. Of course, it is able to generate coating data, and also to reproduce faithfully by receiving coating data from Data-Pro, data generating robot.

High-grade data compatibility realizes Digital Coating.

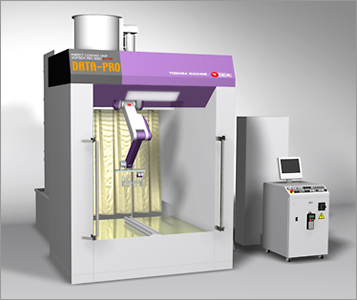

Data-Pro, which was developed for coating test, is a small-sized robot to evaluate coating film, and to process various kinds of basic information including coating time, coating material consumption volume, coating cost calculation and others. All information in the coating test, such as teaching data and coating conditions with spray setting, becomes digital data. Data about condition setting and so on can be sent by e-mail. If there is a SOFTBOY PRO series or Line Dancer in the factory to receive the data, the coating can be reproduced. That is, it will be possible to reproduce exactly the same quality which was taken from the test. In case that there are production bases located all over the world, Data-pro is able to solve the lack of unity in quality and cost by place so that the headquarters in Japan can control them.

- Control and Compatibility of Coating DataVideo

-

Control and Compatibility of Coating Data

DATA-PRO