[Cost/C.M. consumption/Used amount/Color change]

How could you reduce used amount of coating materials?

First of all, a system possible to control used amounts is necessary to know appropriate coating material consumption volume.

Precise control of coating material supply

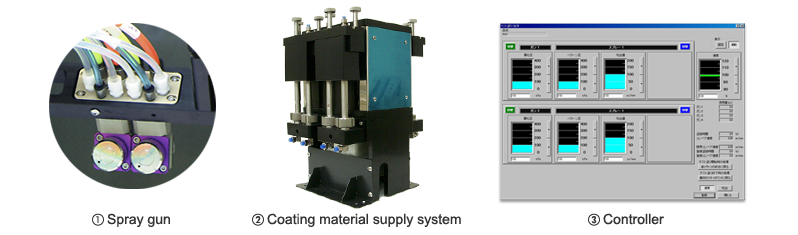

One of the important factors to decrease coating material consumption volume is ① Spray Gun.

The atomization ability in low pressure should be excellent. And the next is ② Coating material supply system. In case of a conventional system of diaphragm pump with a simple pressure method, it is not possible to make a stable supply and also it gives a bad influence to the spray by pulsation. Syringe Pump System to control supply volume by 1cc precisely is required.

Furthermore, ③ Controller to control those is very important. Optimum coating film is created to show functions of the coating material by supplying a little paint with a certain volume and also by atomizing it with low pressure. Consequently control of coating material realizes reduction of waste consumption of coating materials.

Discharge control by R-technology, revolving coating

R-technology, in which some smart phones mounted on a circle jig are coated revolving clockwise and counter-clockwise, makes it possible to set discharge pressure, atomizing pressure and pattern pressure at the parts to be coated. Its purpose is to appropriately coat necessary part with suitable volume of paint. It widens the pattern in a large part, and lowers the discharge pressure in a small or rough part. Such settings should be memorized as condition setting. Those condition settings do not depend on feelings of workers but depend on a numerical control by robot. Only the system which can manage numerical control could be an important factor to determine the coating cost.

Particular about consumption volume

In a conventional thought, coating efficiency was a basic element to evaluate a system. Coating material consumption volume is the basic element with which for us to evaluate coating ability of Line Dancer. We are thinking how the high quality performance can be created with a very small quantity of paint. That could be one of the most important points for coating unit price, product assessment and environmental issues in coating management.

by 20% to 50%

- Every kinds of coating materialsVideo

-

Every kinds of coating materials

Suitable to every kinds of coating materials including UV paint